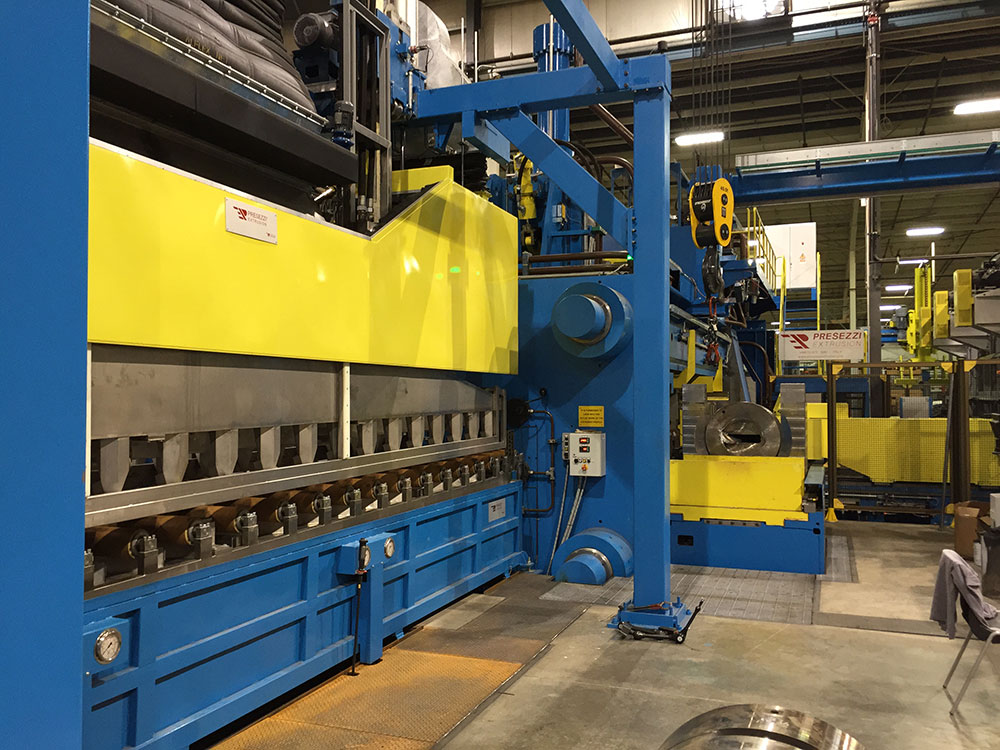

At the exit of the press there is the Presezzi’s "H.E.C.S." cooling system.

"H.E.C.S." means High efficiency cooling system that is characterized by a new pattern of air nozzles that improve the efficiency of the system approximatively of 25% compared to traditional system.

The system is composed by a lower part with high temperature resistant rollway that can move vertically in order to work with different heights of the extruded profiles.

FEM analysis are made in order to provide the best cooling solution and in order to give the most accurate temperatures for the mechanical proprieties of the extruded profiles.

Presezzi can supply different types of intensive cooling system according to extruded alloys, profile dimensions, required temperatures and extrusion speed.

AIR COOLING SYSTEM

- Electric motors with frequency converter for lifting the upper hood.

- Pneumatic safety blocks for securing the hood in upper position and prevent it from falling.

- Centrifugal ventilators with frequency converter on the motors.

- Air blades on the profile sections divided in four zones.

- Gate motorized valves for precise air flow adjustments.

- Kevlar Rollers on the lower part.

AIR & WATER COOLING SYSTEM

- All the features of the Air cooling system.

- Upper and lower parts in stainless steel.

- Air barriers to avoid water escapes toward the press and to dry the profile from residual water.

- Self-cleaning filters.

- Regulation valves for each cooling zone in order to guarantee a very precise water control.

- "Dovetail type" nozzles in order to always guarantee a correct positioning of the nozzles.

- Possibility to supply:

- Water tank in stainless Steel.

- Water recycling with adequate heat exchanger and water softener system.

- Cooling towers.

TANDEM COOLING SYSTEM

SPECIAL SOLUTIONS

- All the features of Air & Water Cooling System.

- Division of the upper hoods in separate and identical sections.

- Higher cooling rates for heavier profiles with high extrusion speeds.

- Better control of the temperature on the extruded profiles.

- Reduction of the scrap of the first billet extrusion.

AIR, WATER AND MIST COOLING SYSTEM

SPECIAL SOLUTIONS

- All the features of Air & Water Cooling System.

- First part of the System (near to the Extrusion press) characterized by presence of the Mist cooling sections.

- Specially designed injectors.

- Proportional valves for compressed air and water controls.

M.P.C.T. COOLING SYSTEM

SPECIAL SOLUTIONS

- Upper and lower parts in stainless steel.

- Modular structure divided into identical cooling sections.

- Electric motors with frequency converter for lifting the upper hoods.

- Pneumatic safety blocks for securing the hoods in upper position and prevent it from falling.

- Air barriers to avoid water escapes toward the press and to dry the profile from residual water.

- Especially movable designed injectors.

- Upper injectors pneumatically moved in order to guarantee completely cover of the entire surface of the extruded profiles.

- Proportional valves for compressed air and water controls.

- Special Energy saving air compressors with fixed and variable speeds.

- Additional high pressure water nozzles in order to increase temper range of particular profiles.